Slowly apply pressure the piston should slide out under the air pressure. Hold the air gun firmly in place to provide a tight seal.

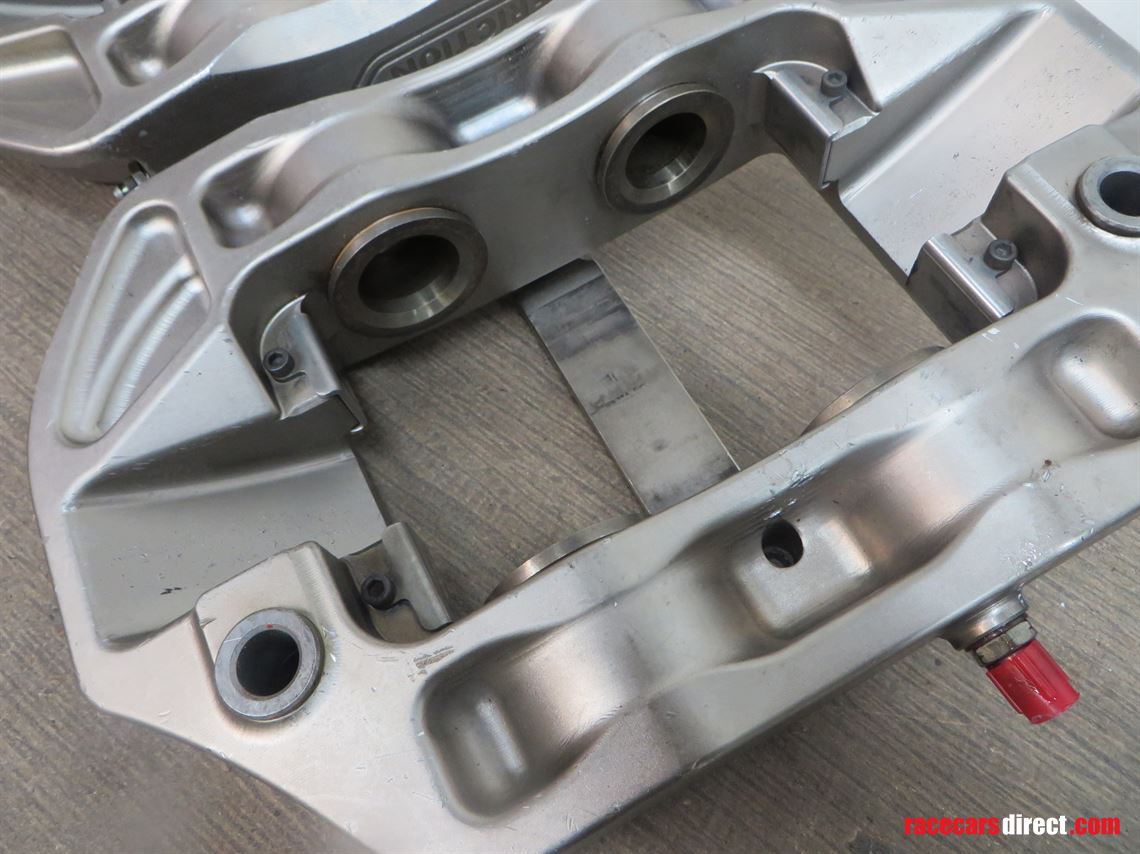

Place the rubber tipped blow gun in the main hole where the brake line attaches. I use the clamp as a safety device for the next step so the piston cannot fly across the shop. Use a small amount of grease to keep the seal in place while installing the plate.Īfter the dust seal is removed and the block-off plate is installed, place the C-clamp back on the caliper but do not tighten it. Because the internal hex bolts are too long, the large hex nuts are necessary to tighten down the block-off plate. Mount the block-off plate on the caliper using the existing caliper internal hex bolts and two large hex nuts. Using the old center caliper seal, place the seal over the crossover hole in the caliper. Hole placement can easily be determined by using the bleeder-side caliper half as a template. Drill two holes that line up with the two bolt holes in the caliper. This can be accomplished with a small piece of aluminum, 0.020 inch minimum thickness will do. The crossover hole will need to be blocked off. The main problem with the outer-side caliper is being able to pressurize the caliper since there are two holes, one where the line hooks up, and one where it crosses over to the other half of the caliper. This will take some patience and a little effort. Remove the dust seal (the slightly exposed rubber seal) from the caliper with a pick. Remove the clamp to allow for the dust seal removal. Be careful as the old fluid will be ejected from the caliper. Use the C-clamp and compress the piston so it bottoms out against the caliper body. Carefully clamp the caliper half in the vise so the piston is not obstructed by the jaws. Split the caliper in half by removing the two large bolts and the two internal hex bolts. Once the brake caliper is out of the bike it will need to be taken apart. A heat source such as a heat gun or propane torchīegin by removing the brake caliper.Some special tools are required, but they are available from any local tool and hardware store. If you can master the dual piston caliper, the single piston caliper will be a breeze. In this example, I used a dual piston caliper found on the Yamaha RD’s, XS’s and TX’s. Here is a great way to get those stuck pistons out of the calipers. This is not a good look for a restoration it’s really not even a good look for a daily driver. Some are quite crude, such as drilling a hole through the caliper, pushing the piston out and then plugging the hole with a household pipe thread plug. Over the years I have seen many solutions to this problem.

The main problem is getting the pistons out of the calipers. Now you are faced with repairing the brakes, replacing the seals and perhaps the rusted pistons.

Then the front brake pistons no longer move in and out or in the worst case, the brakes are frozen solid to the brake disc. Disc brakes are great until the bike sits for a long time, when the metal housings start to rust and the fluid turns into a jelly-like goo.

Brake caliper piston upgrade#

On the contrary, since the disc brake hit the market in the early 1970’s, it has been a great performance upgrade to the older drum style brakes. Some of you might think of a vintage motorcycle as having only drum brakes.

0 kommentar(er)

0 kommentar(er)